Interview with Acuity Process Solutions

Highlights from our interview with Jim Bodle from Acuity Process Solutions, a long-time distributor, partner, and trusted solutions provider to various high-purity process industries:

Q: What was the problem you were trying to solve when you decided to use Eilersen load cells?

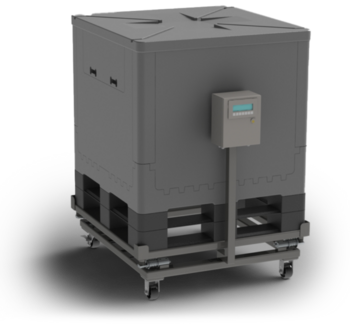

A: As the life-science industry increasingly adopts single-use technology and mobile equipment, they face challenges about how to best measure liquid volume. Load cells are a great way to measure liquid volume, but mobile totes, carts, and mixers present unique concerns due to the extraneous forces that they encounter during movement in a facility. The traditional strain- gauge Load cells mounted on mobile application can lose calibration or cause frequent deviations due to old-style mounting kits and mandatory overload protection.

Q: How has Eilersen load cells helped you solve this problem?

A: The Eilersen capacitive load cells are very robust and can handle significant side-load, overloading, and torsional forces without concern. They do not need mounting kits to protect them and do not lose calibration. This leads to fewer deviations and less downtime and offers customers a maintenance free weighing solution.

Q: Are there any specific features or benefits of Eilersen load cells that you find particularly valuable?

A: There are a significant number of benefits to our clients. The reliability and robustness of the Eilersen load cells is substantially better than other technologies and the fully-digital measuring chain, ease of installation, and extremely hygienic design are critical to our life-science customers.

Q: Have you seen any tangible results or improvements since using Eilersen load cells?

A: Just the investigation into a deviation is a significant cost for a life-science customer. In addition, any product loss, or production interruption can be substantial. We find that our clients see the reliability and savings to be so significant that the cost of replacing older strain-gage based solutions with the Eilersen system can be easily justified.

Q: How has Eilersen load cells impacted your business/organization?

A: Without doubt, Eilersen offers a product that is a market leader and their customer support is unprecedented. We are confident that we are offering the best solution in the industry.

Q: Can you share any specific success stories or examples of how Eilersen load cells has helped you achieve your goals?

A: It seems to me that everyone in the industry has had at least one bad experience with load cells. The majority of load cells in the US Life Science market are strain-gauge based technology which must be equipped with protective mounting kits that are locked out before moving the tank or tote. Eliminating the need for this saves time, money, and ergonomic concern, making for a more hygienic, reliable installation. This issue is becoming more and more critical as the volume in the mobile applications increases.

Q: Would you recommend Eilersen load cells to others? If so, why?

A: Definitely. We do it every day.