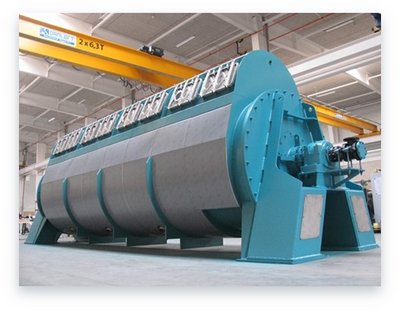

Typically, a meat rendering machine from Oestergaard A/S is installed on four compression load cells and must operate under the following conditions:

- A total working weight of up to 200 tons

- Internal working temperatures ranging from 40°C to 180°C

- Horizontal expansion of the machine, of up to 20 mm

- Welding on machines during installation often occurs

The Eilersen capacitive load cells have proven remarkably reliable over the years, with several beneficial features compared to traditional strain gauge load cells. For machines using Eilersen digital load cells, it is possible to monitor the load distribution on each load cell which is beneficial to ensure correct installation. The individual Eilersen digital load cells even send an error code if maintenance should be required for fast and easy trouble-shooting. But apart from features, it is the durability of Eilersen load cells that seems to impress customers experienced in weighing technology. Even though it is not recommended, employees at Oestergaard A/S often need to weld on or close to machines installed on load cells. Anders Juul, Project Manager at Oestergaard A/S explains:

“Often, welding is required during the installation process, which often damages a strain gauge load cell, causing expensive delays as we need to order express delivery of replacement load cells to customer sites. However, we have not experienced damaging the Eilersen load cells since we started using them many years ago, even when welding on the machines.”

Eilersen load cells installed a decade or more ago - some even 30 years back - have been operating with the same accuracy and reliability as when they were new, despite being exposed to high horizontal loads and frequent overloads.